Discovering Flaws and Faults and identifying the sources of spirit flaws that affect the quality of spirits often begs the question “What’s that horrible smell? Nail polish, kerosene, tri-chlor, dead rodent, rotten eggs, vomit?” These are just a few comments heard over the years from spirits tasters. In this presentation, we will examine the source of flaws in the spirit, some of the many revulsive aromas, and their potential causes. The cause of flaws in spirits is a complex subject, and this presentation should be considered as no more than a simple overview, as many books in-depth studies, and journal papers have been written about each of these problems.

The purpose of this presentation is to raise awareness regarding the difficulties in producing high-quality spirits and to provide some clues to the evaluator in recognizing potential flaws. Over the next two presentations, we will discuss various aspects of faults and flaws, including input from experts and scientists who are intimately familiar with the chemistry and smells of the distilling process. From Alan Gordon, CEO and co-founder of Aroma Academy:

Discovering Flaws and Faults in Spirits

Introduction

When discovering flaws and faults, considering Spirits flavors in general, and the development of flavor sensory skills, in particular discovering flaws, it is useful to categorize flavor descriptors into two broad categories, namely, Positive and Negative.

Understanding positive flavor attributes is vital for both

- product development, where companies are creating and developing interesting flavor profiles that differentiate them from the competition, and

- production where quality control is focused on ensuring the consistency of flavor profile from batch to batch.

However, detecting and identifying negative flavor attributes (or ‘Faults’) is also fundamental in both these phases. This need is obvious in Spirits production as no company wants to produce faulty products for both cost and reputational reasons and, therefore, early Fault identification is vital. Perhaps less well understood is the fact that understanding Faults is also key in the creation and development phase as companies strive to develop robust products and processes that have the lowest probability of developing flavor Fault types.

What is a Fault and where do they come from?

Let us first take a step back and ask the question – What is a Fault? The answer is ’It is dependent on the context’ as what may be considered a positive attribute in one spirit type (for example a smoky note) may be a Fault in another if it is not part of the intended profile!

Part of the challenge in drinks development and production is that the potential sources of Faults are myriad and can be both internally and externally generated. The broad potential source categories may be listed as;

- Raw Materials

- Processing

- Storage

- Maturation

- Degradation

- Contamination

It is interesting to note that there is a broad subset of Spirits Faults/Defects that is also common to wines and beers but, in the Spirits category, the additional potential issues from areas such as distillation and longer-term cask maturation must also be considered. Let us consider just some of the typical/common Faults in Spirits production, some of which are related to internal processing and some of which are external/contamination-related.

Processing: Fermentation

A common process across many drink types is ‘fermentation’ and the impact of defective or incorrectly processed raw materials or yeast can give rise to many fermentation-related issues. Although less high profile than in wine or beer, the impact of yeast type and processing is also significant in the flavor profile of spirits.

Established distillers develop their own bespoke ‘inhouse’ yeast of choice over many years. They are joined by the many distillers who use what is termed ‘distiller’s yeast’ – yeast that is very carefully developed and produced by specialist yeast companies. In each case, the objective is the same, which is to ensure consistency of output. However, several producers – particularly craft distillers – are advocates of the use of ‘wild yeast’ which can provide a multitude of different and varied flavour elements allowing increased brand differentiation – although this also provides the downside risk of more potential unpredictability with the danger of the creation of possible flavour faults. Potential faults, that must be monitored, include the excess presence of acids such as isovaleric acid which makes its presence known with a distinct ‘cheesy’ or even ‘vomit’ type aroma/flavour note, or volatile phenols such as 4-ethylphenol providing aroma/flavour notes described as reminiscent of anything from leather to a barnyard!

Processing: Distillation

Most people will be familiar with the concept of the distillation ‘cut’ where Spirits distillers aim to capture the ‘Heart’ of the distillation and eliminate the unwanted ‘Heads’ and ‘Tails.’ Distillers and QC staff must be trained to detect and identify the aromas/flavors of these unwanted elements and monitor for potential aromas/flavor Faults. The ‘Heads’ Faults include excess elements such as Acetaldehyde (with its volatile vaguely ‘apple-like’ fruity aromas), Acetone, Methanol or Ethyl Acetate (with its classic ‘solvent-y’ aroma.)

Acetaldehyde

The unwanted heavier notes from the ‘Tails’ represent the final elements of the distillate which are low in ethanol and high in unwanted components including alcohols such as Butyl Alcohol, Amyl Alcohol, and other elements such as Furfural with its mix of flavor notes including almond and caramel.

Butanol

Another key element of the distillation process is the removal of excess sulfur compounds – typically by providing exposure to an appropriate level of copper. Excess sulfur can manifest itself in many ways in the aroma/flavour profile with unwanted notes ranging from excessive vegetable (such as overcooked cabbage) to garlic/onion-type notes or even burnt rubber.

Processing: Maturation

Spirit maturation in casks provides another opportunity for Faults to develop ranging from the simple factor of a cask becoming contaminated with some type of funghi to issues such as the spirit being exposed to the cask for too long and taking on ‘too much flavour’ from the wood (for example an excess of ‘vanilla’ flavour) which overpowers the overall flavour profile.

External Contamination

There are many sources of possible contamination from external sources, and we describe a couple of examples below. A simple factor that is often overlooked is the quality and consistency of the water which is typically added to the distilled spirit to achieve a desired final abv. Care must be taken to ensure that the water does not have an excess of elements such as chlorine which will distort or overpower the final flavor profile – or the presence of elements such as Geosmin which can provide an unwanted dominant ‘earthy’ profile. (The name Geosmin is based on ‘Geo’ – ‘earth’ and ‘Osme’ – ‘odor’ and typically has the aroma of damp soil.)

The final external contamination example that we highlight is the issue of Spirits that are ‘corked.’ This is typically less of a problem in the world of Spirits as compared to Wine – where it has been a massive issue for decades – but this Fault is also seen in Spirits, particularly in Spirits with cork closures. One of the key culprits is a molecule known as TCA (2,4,6trichloroanisole) which is created when an element of chlorine (typically via some type of chlorinated cleaning product) makes contact with a particular type of mold – typically on corks but it can also be generated on other items such as packaging or pallets.

TCA

The resulting Fault is detected as a musty wet newspaper/damp cloth aroma/flavor which is not only unpleasant in its own right but also has the effect of attenuating the overall flavor profile. It should be noted that if this Fault finds its way into drinks production facilities it is notoriously difficult to eliminate.

Summary

In Summary, potential Faults in Spirits are many and varied and may appear from many possible sources, only a few of which, we have introduced above.

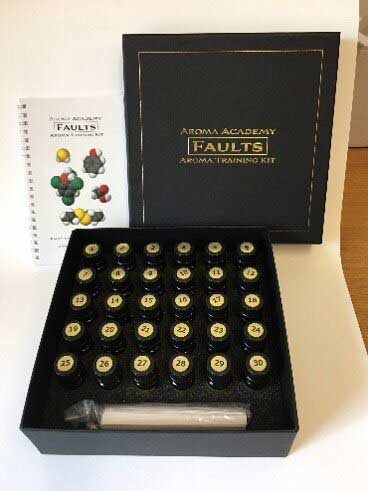

At the Aroma Academy, we provide comprehensive sets of Faults Standards Kits and Sensory Faults Training to allow familiarization with typical drink Faults and to facilitate the development of the necessary skills for their detection, identification, and articulation.

For product creators and producers, knowledge of the type of Fault which is present, can signpost the appropriate root cause source to allow appropriate corrective (and future preventative) action to be undertaken – be it related to material, processing, maturation, or external contamination.

Knowledge of fault types is also important for drinks buyers, retail staff, professional bartenders, and a whole range of people with a commercial interest in the drinking world. They are joined by a growing band of drinks enthusiasts for whom the end objective is simply to gain further knowledge and insight into the wonderful world of Spirits! Discovering faults and flaws is very much dependent on using a properly designed glass such as the NEAT glass.

CEO & Co-Founder